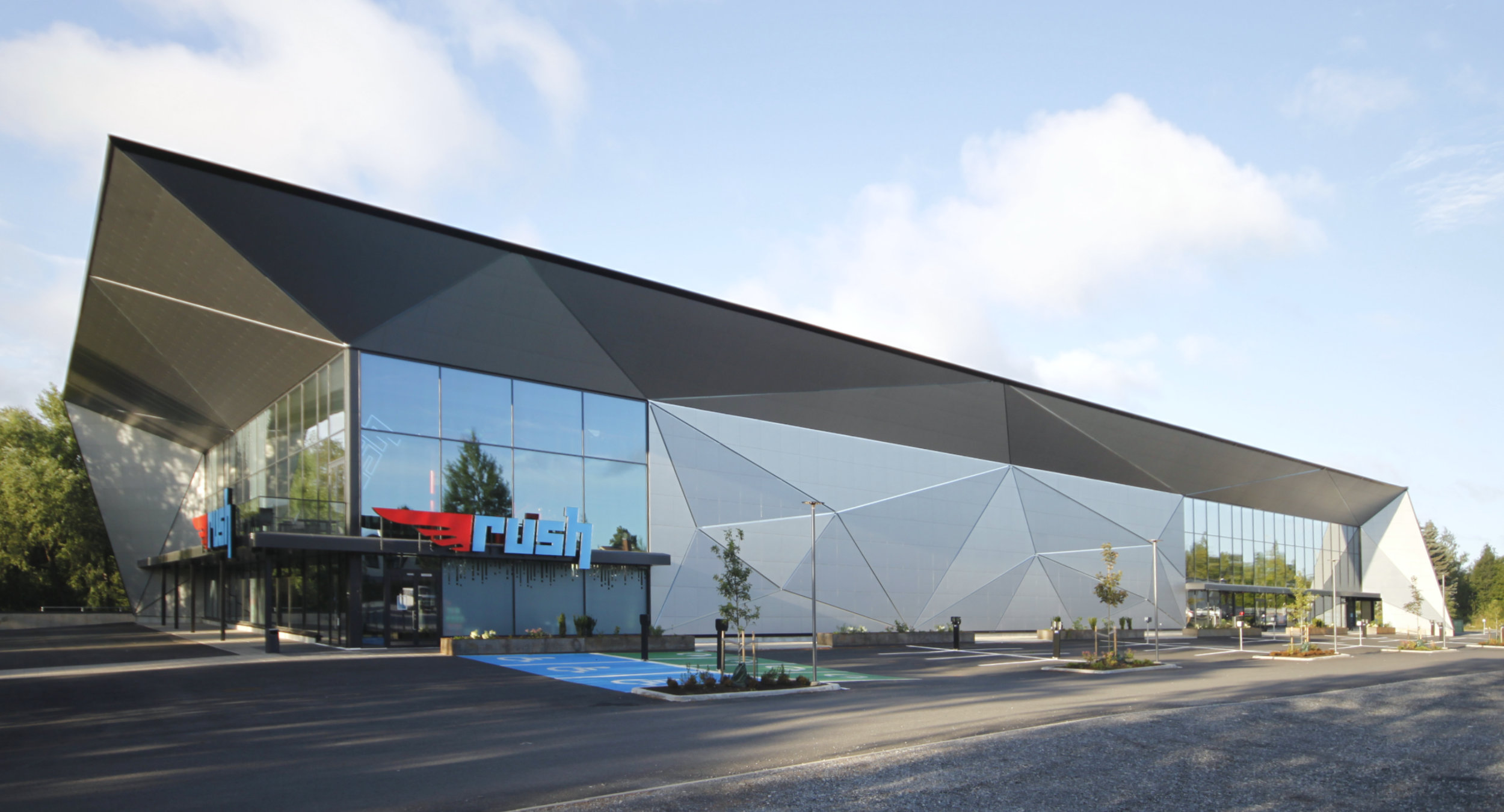

Geometria was commisioned by Trutec construction company, with the Design for Manufacture and Assembly (DfMA) of the aluminium façade panels and their supporting substructure. Our scope focused on modelling the practical solutions that aligned with both architectural intent and production efficiency.

Geometria handled the façade optimization, fabrication modelling and planning for this project.

Our work started with estimating material quantities for procurement. We then divided and optimized the triangulated façade design, breaking it into panels using a 1200×1200 mm grid system – making sure each triangular section had the correct brushed aluminium finish orientation for the right visual effect.

To reduce material waste, we created a nesting strategy that fit these panels efficiently into 1500×3700 mm aluminium sheets during fabrication. We also planned the installation of both the façade panels and the back-structure, which used four different beam profile types for proper structural support and efficient installation.

End client: Worknest Oy

Operator: Rush

Facade contractor: Trutec Oy

Architects: Arkkitehdit LSV

Structural design: Insinööriavain Oy

Facade DfMA: Geometria Architecture Oy

2025

Tampere, Finland

Trutec OY

Completed

Geometria & Arkkitehdit LSV

Consulting, Fabrication