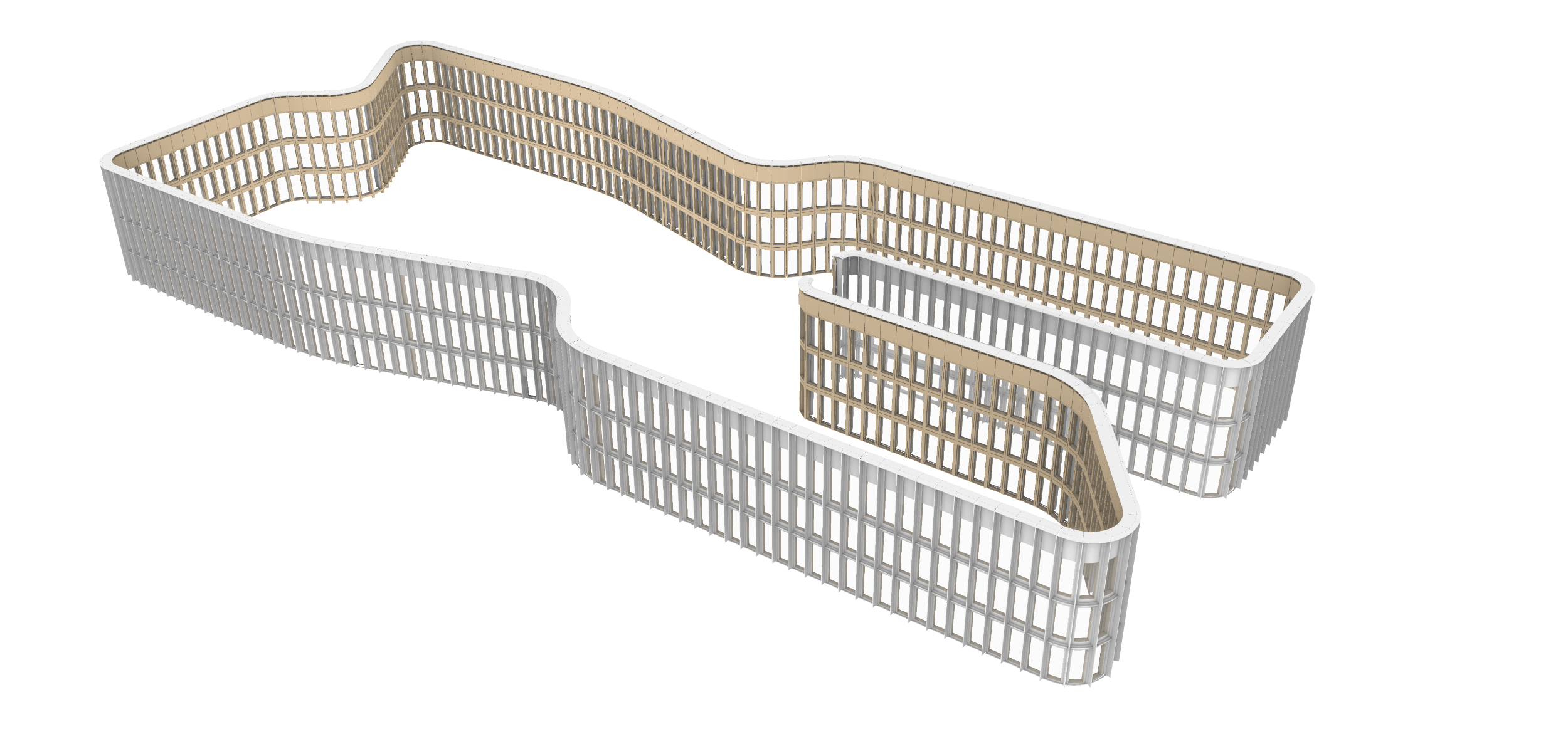

Katajanokan Laituri, designed by Antinen Oiva Arkkitehdit, is the largest timber building of its time in Finland measured by the amount of timber used in its internal structure.

Katajanokan Laituri, designed by Antinen Oiva Arkkitehdit, is the largest timber building of its time in Finland measured by the amount of timber used in its internal structure.

Acting as the headquarters of Stora Enso as well as a hotel, the prominent building in the heart of the Helsinki seafront boasts impressive 7.600m3 of spruce in its structure as CLT, glulam and LVL.

The building has a long, undulating double façade designed to withstand the harsh sea climate and protect the wooden structure within.

Working for the facade contractor Haka pks Oy, Geometria led the Design for Manufacture and Assembly (DfMA) process for the building’s curved double facade.

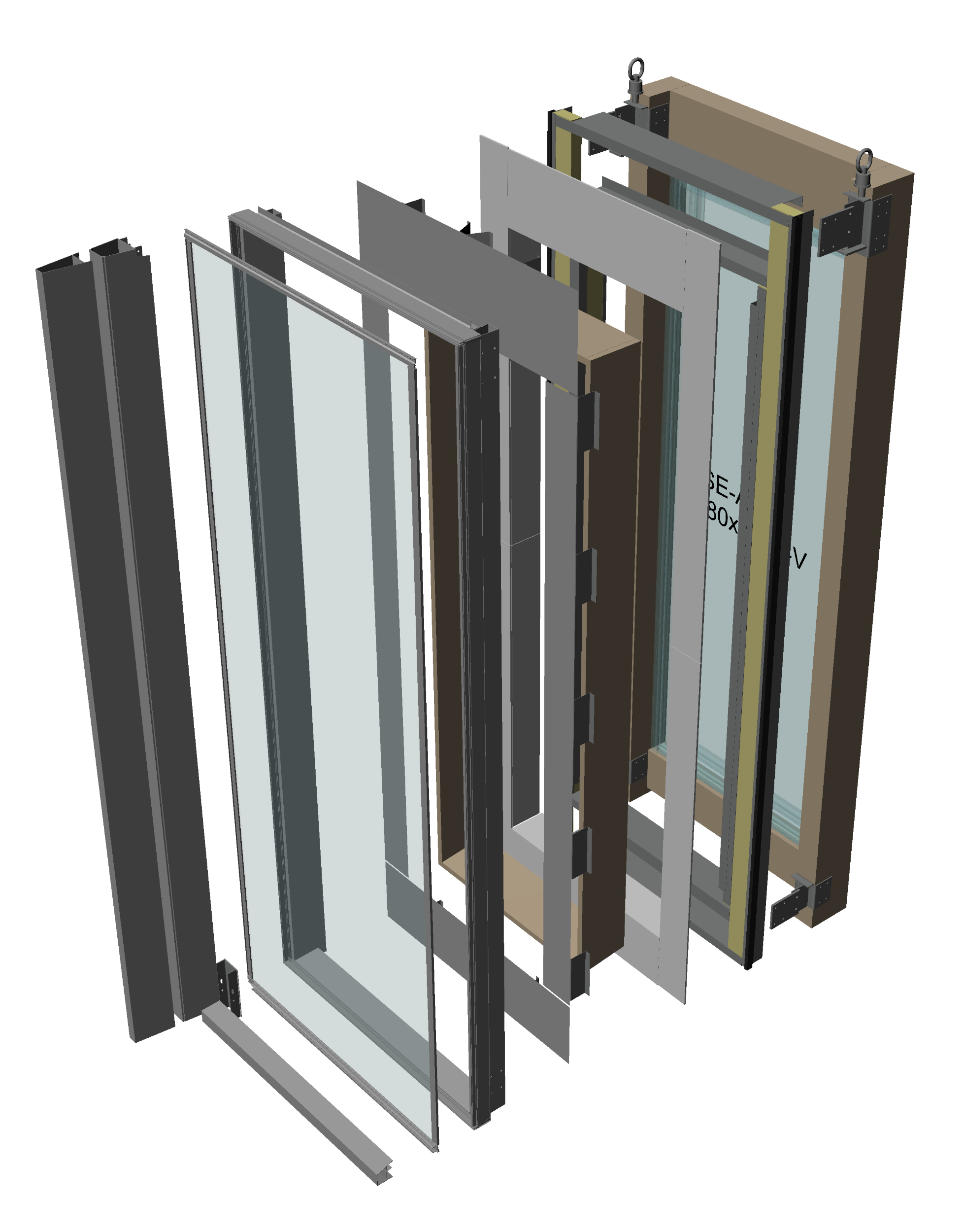

As the Katajanokan laituri building was divided into 586 prefabricatable element, Geometria’s first task was to categorise the elements to unique types based on the dimensions of the interior façade LVL frame. This task resulted in only 170 geometrically unique element types, or 298 if counting variations in factors such as glazing types.

Each prefabricated facade element assembly consists of almost 200 documentable parts. Variation is increased by mediating the gap between the polygonal interior structure and the smoothly curved exterior façade surface.

The categorised facade elements could be divided into three main types: straight, curved with symmetry, and asymmetric. Asymmetric types were found in the intersection between linear and arc sections of the façade.

For modelling of the entire facade with fabrication-level accuracy, we created numerous small and medium-sized automated Grasshopper scripts.

Based on the 3D model and its metadata, Geometria generated 1,252 dimensioned part fabrication drawings and 1,740 element assembly drawings. As well as numerous spreadsheet-listings and toolpaths for CNC-machines.

The CNC toolpaths for the aluminium parts were generated directly from the 3D model using an ad-hoc Grasshopper tool.Some wooden parts were outsourced for fabrication based on .stp models.

Because of the impressive amount of preplanning and prefabrication, the installation of the facade elements on the construction site only required four drawings.

Developer: Keskinäinen työeläkevakuutusyhtiö Varma

Architectural design: Anttinen-Oiva Architects Oy

Structural design: Sweco Finland Oy

Main contractor: Haahtela-rakennuttaminen Oy

Timber provider: Stora Enso (CLT, LVL), Punkaharjun Puutaito Oy (LVL)

Timber components, lobby: Raision Puusepät Oy

Facade contractor: Haka pks Oy

Facade DfMA: Geometria Architecture Oy

2025

Helsinki, Finland

Hakapks Oy (facade contractor)

Completed

Facade area about 5.300 m2

Consulting, Fabrication